Emulsifiers: Secret Ingredients for Attaining Perfectly Mixed Solutions

Emulsifiers play a necessary role in producing secure mixes of immiscible fluids, such as oil and water. Their distinct residential or commercial properties enable them to lower surface stress, which is vital for harmony in various formulas. Recognizing the differences between synthetic and all-natural emulsifiers can influence product high quality considerably. As markets significantly look for to improve texture and life span, the selection process for the best emulsifier comes to be critical. What variables should be considered in this critical choice?

Recognizing Emulsifiers: What They Are and Exactly how They Function

Emulsifiers may seem like an easy addition to solutions, they play a vital function in supporting blends of components that usually do not blend well, such as oil and water. These compounds function by decreasing surface tension at the user interface in between immiscible liquids, allowing them to mix even more evenly. Emulsifiers have both hydrophilic (water-attracting) and lipophilic (oil-attracting) residential or commercial properties, which enable them to secure themselves at the border of both stages. By doing so, they produce a protective obstacle that protects against the beads of one liquid from coalescing into bigger masses, therefore preserving a steady emulsion. The performance of an emulsifier relies on its molecular structure, which influences its ability to maintain blends. In various applications, from food to cosmetics, emulsifiers ensure a consistent texture and look, enhancing both capability and customer appeal. Their relevance can not be overstated in achieving well-blended solutions.

Kinds of Emulsifiers: All-natural vs. Artificial

Emulsifiers can be broadly classified into 2 types: all-natural and synthetic, each offering distinctive advantages and applications. All-natural emulsifiers, stemmed from plant or pet sources, consist of lecithin, gum, and casein arabic (emulsifiers). These emulsifiers are usually favored in natural and clean-label items due to their very little processing and biocompatibility. Their gentle nature makes them ideal for sensitive formulas, especially in food and cosmetics

On the various other hand, artificial emulsifiers such as mono- and diglycerides, and polysorbates are manufactured through chemical processes. They are typically made use of in commercial applications due to their stability and effectiveness in developing solutions. Synthetic emulsifiers typically display premium performance in extreme problems, such as heats or varying pH levels. The choice between all-natural and artificial emulsifiers greatly depends on the particular formula demands, governing factors to consider, and customer choices, affecting their effective application in various industries.

Functions of Emulsifiers in Food and Cosmetic Formulas

The function of emulsifiers prolongs beyond simple stabilization; they are essential in accomplishing the wanted appearance, shelf, and texture life of food and cosmetic items. In food solutions, emulsifiers aid mix oil and water, developing smooth and consistent appearances important for sauces, dressings, and dairy products. They decrease surface stress, boosting the security of emulsions, which avoids separation and prolongs quality.

In cosmetics, emulsifiers assure that components, such as oils and water, mix effortlessly, supplying a pleasurable feel and improving application. emulsifiers. They add to the product's thickness and spreadability, necessary for lotions, products, and creams. Furthermore, emulsifiers can encapsulate energetic ingredients, improving their circulation and effectiveness in solutions. By managing structure and enhancing sensory qualities, emulsifiers play an important duty in meeting customer expectations in both food and cosmetic industries, ensuring products are not just appealing yet also functionally reliable

Choosing the Right Emulsifier for Your Item

In addition, the target application-- whether for food, cosmetics, or pharmaceuticals-- will certainly influence the selection. my website Food-grade emulsifiers should abide with safety and security regulations, while aesthetic emulsifiers may need skin compatibility. Examining elements such as HLB (Hydrophilic-Lipophilic Equilibrium) helps in forecasting emulsifier behavior in certain formulations. Eventually, a comprehensive analysis of both functional requirements and governing considerations is necessary to pick the most efficient emulsifier, making certain the end product fulfills the desired high quality and security standards.

Tips for Successful Solution Development and Security

Accomplishing successful emulsion development and security needs careful interest to numerous critical factors. Initially, the choice of emulsifier plays a crucial function; it should be suitable with the oil and water phases to ensure efficient stablizing. Second, the proportion of oil to water should be well balanced, as an improper proportion can lead to instability. Third, the mixing procedure ought to be managed; high shear blending can aid achieve smaller sized droplet sizes, improving security.

Temperature likewise affects emulsion security; maintaining optimal temperatures throughout formulation avoids early splitting up. Additionally, integrating stabilizers such as thickeners can even more improve viscosity, minimizing the likelihood of phase splitting up. Ultimately, conducting extensive security tests after solution will help determine possible concerns, allowing for modifications prior to last production. By adhering to these guidelines, formulators can accomplish constant and reliable emulsions that maintain their desired buildings with time.

Regularly Asked Inquiries

Can Emulsifiers Be Made Use Of in Vegan Formulations?

Yes, emulsifiers can be made use of in vegan solutions. Lots of plant-based emulsifiers, such as lecithin the original source from soy or sunflower, supply efficient blending without animal-derived active ingredients, making them suitable for a variety of vegan items.

What Prevail Allergens in Emulsifiers?

Common allergens in emulsifiers consist of soy, milk, and eggs, as specific emulsifiers are stemmed from these resources. In addition, some individuals might respond to chemicals or ingredients utilized alongside emulsifiers in various formulations.

How Do Emulsifiers Effect Rack Life of Products?

Emulsifiers boost item security by preventing separation of components, consequently expanding life span. They minimize spoilage triggered by microbial growth and oxidation, leading to long term quality and enhanced quality in different food and aesthetic formulas.

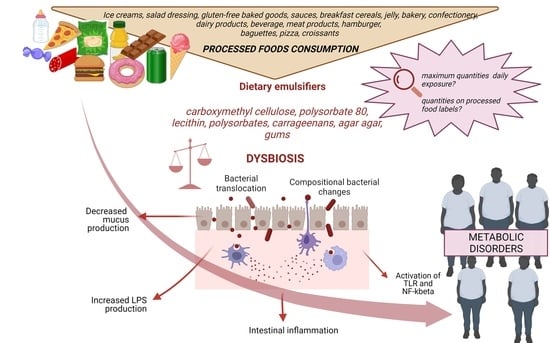

Exist Any Type Of Health Problems Connected With Emulsifiers?

Research study suggests potential wellness worries related to emulsifiers, including intestine microbiome modifications and inflammation. While governing bodies typically deem them risk-free, ongoing researches remain to explore lasting effects on wellness and general well-being.

Can Emulsifiers Improve Taste or Aroma in Formulations?

Emulsifiers can enhance taste and aroma in solutions by enhancing ingredient diffusion and stability. This causes a much more consistent product, enabling flavors to fuse efficiently, inevitably causing a more satisfying sensory experience for consumers.

Emulsifiers might seem like a simple enhancement to formulations, they play a crucial function in maintaining mixes of active ingredients that usually do not mix well, such as oil and water. In food formulas, emulsifiers aid blend oil and water, developing consistent and smooth textures vital for sauces, dressings, and milk products. Food-grade emulsifiers must abide with safety policies, while cosmetic emulsifiers might call for skin compatibility. Usual allergens in emulsifiers include soy, dairy products, and eggs, as certain emulsifiers are acquired from these resources. Emulsifiers can enhance flavor and scent in formulations by improving ingredient dispersion and stability.